Una nuova generazione di sensori wireless

I sensori wireless WiEgg hanno delle innovative caratteristiche tecnologiche e sono la soluzione ideale per innumerevoli utilizzi sia in ambiti professionali che domestici.

BASSO CONSUMO

Tutti i sensori sono alimentati con una batteria interna che garantisce diversi anni di funzionamento e non richiedono alcuna connessione alla rete elettrica.

TRASMISSIONE A LUNGA DISTANZA

Il modulo wireless installato su ciascun sensore può trasmettere i dati a distanze molto elevate, anche di parecchi chilometri.

NESSUN OPERATORE TELEFONICO

La trasmissione dei dati dei sensori avviene su una banda radio di libero utilizzo e quindi senza costi di gestione.

BASSO COSTO

La tecnologia di ultima generazione utilizzata per la progettazione e la produzione, ha permesso di contenere i costi dei sensori a livelli senza precedenti.

Prodotti e servizi

Prodotti e servizi

Wiegg Solar

Un’innovativa soluzione per impianti fotovoltaici di qualunque dimensione e tipologia, che consente di monitorare in continuo la produttività di ogni singola stringa di moduli e di segnalare tempestivamente accessi non autorizzati in prossimità dei moduli o di altre componenti dell’impianto.

Wiegg Lighting

Sistema per la regolazione wireless dell’intensità luminosa delle lampade LED, particolarmente indicato in ambiti commerciali, industriali, produttivi e uffici sia indoor che outdoor: riduce ulteriormente i consumi elettrici e migliora il comfort visivo.

Wiegg Urban

Wiegg Ping

Wiegg Guard

Sistema per la regolazione wireless dell’intensità luminosa delle lampade LED, particolarmente indicato in ambiti commerciali, industriali, produttivi e uffici sia indoor che outdoor: riduce ulteriormente i consumi elettrici e migliora il comfort visivo.

Wiegg Ping

La soluzione per enti e società che gestiscono attività di Soccorso Alpino, escursionismo e trekking, competizioni podistiche e sciistiche, Regioni e Comunità Montane, associazioni di albergatori quale ulteriore servizio ai propri clienti.

Wiegg Guard

Sistema di rilevamento del movimento di persone o mezzi in ambienti interni o esterni che si basa sull’utilizzo di sensori wireless di elevata qualità, autoalimentati e in grado di trasmettere i dati a distanze elevate, anche di molti chilometri.

Rilevazione automatica di accensione e spegnimento

di un corpo illuminante

Scopri i sensori di corrente Wiegg per gli impianti fotovoltaici

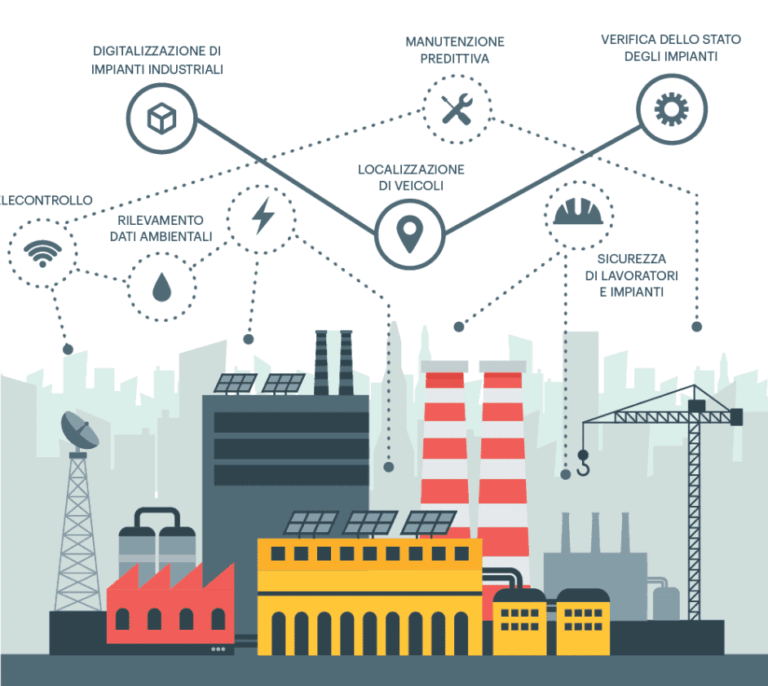

PROGETTI CUSTOM E INDUSTRIAL IOT

WiEgg è specializzata nella progettazione e produzione di sensori wireless di qualsiasi tipo, nella trasmissione remota dei dati misurati e nel controllo a distanza di apparecchiature e dispositivi elettrici o elettronici.